Converting ordinary (and not so ordinary) materials into insulation products.

Sigma VaporPhase™ technology allows for the modification of virtually any substrate to enhance its thermal properties. Films, fabrics, papers, foils, etc. - all can be made to reflect radiant heat with little to no impact on weight, breathability, hand, and other physical characteristics.

Low Emissivity Insulating Fabrics

Woven, knit, and nonwoven fabrics are treated to reflect, rather than emit, radiant heat to dramatically improve thermal performance for applications that include consumer apparel, workwear protection, window coverings, and more.

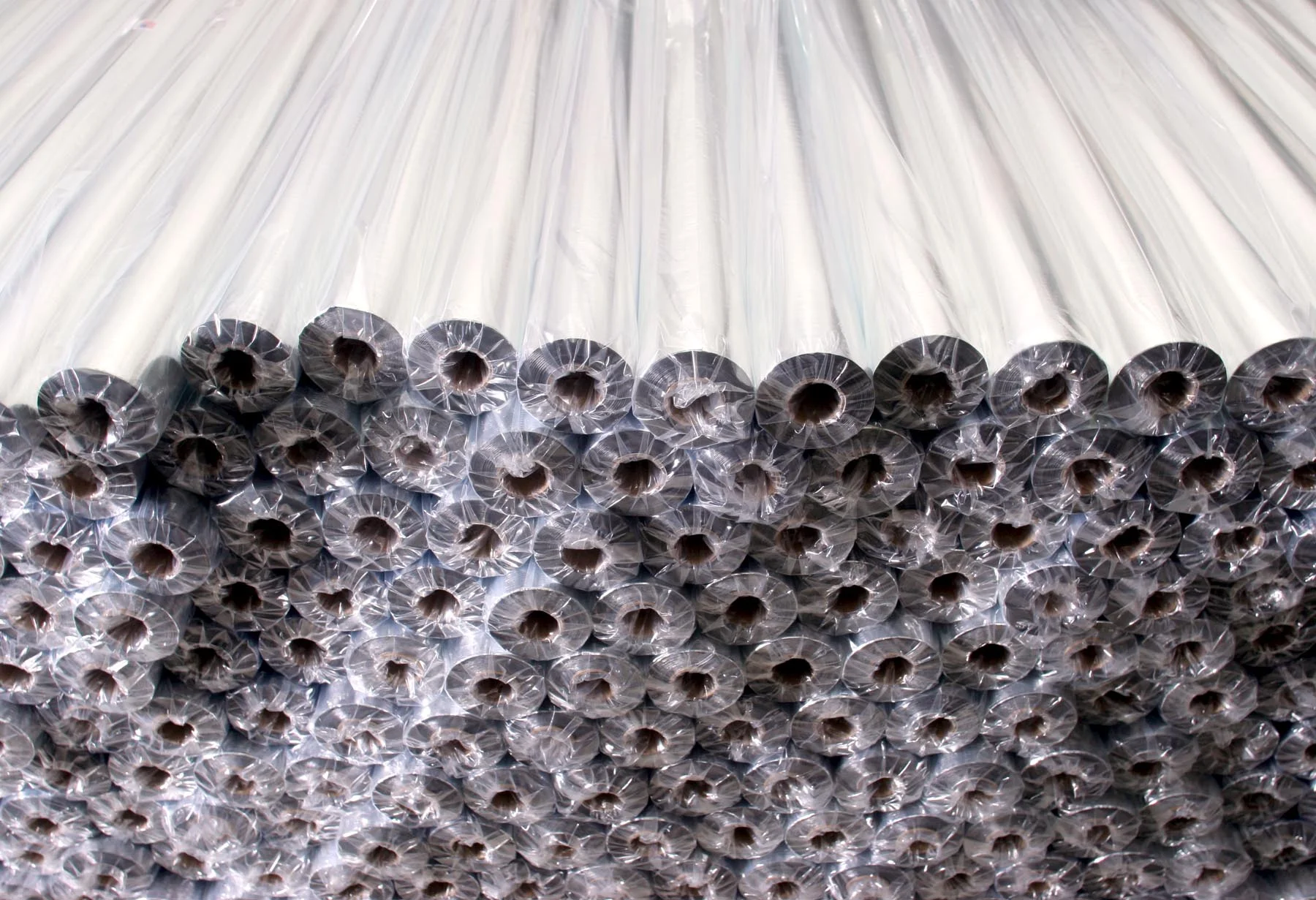

Heat Reflective Films

Polymer films and are coated to exhibit super-low emissivity values. Actual values achieved can depend substrate topography and the reflective material(s) used, which can include aluminum, copper, silver, and multi-layer optical filters capable of reflecting IR while maintaining transparency in the visible spectrum.

Infrared Reflective Pigments

High aspect-ratio pigments, or ultra-smooth multi-layer "flakes," can be used in inks, paints, coatings, plastics, or in dry form to reflect broad band IR or select wavelengths in the IR spectrum. Certain materials or layer structures can feature a high degree of transparency in the visible. Flakes composed of copper or brass, for example, exhibit excellent reflectivity in the IR while providing some concealment in the visible range.